Glossary of Roofing and Waterproofing Terms

E

A B C D E F G H I JK L M N OP R S T UV W-Z

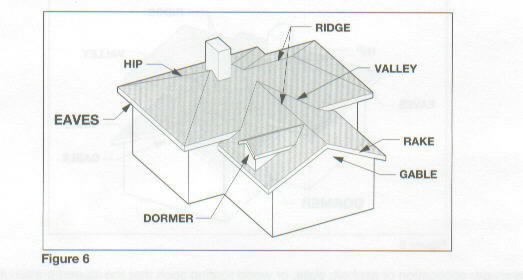

Eave: a projecting edge of a roof that extends beyond the supporting wall. (See Figure 6.)

Eave Height: the vertical dimension from finished grade to the cave.

Eaves-Trough: see Gutter.

ECH: polyepichlorohydrin, commonly referred to as epichlorohydrin. (See Epichlorohydrin.)

Edge Stripping: membrane flashing strips cut to specific widths used to seal/flash perimeter edge metal and the roof membrane.

Edge Venting: the practice of providing regularly spaced or continuously protected (e.g., louvered) openings along a roof edge or perimeter, used as part of a ventilation system to dissipate heat and moisture vapor.

Efflorescence: the formulation of crystalline deposits, generally whitish in color, on the surface of stone, brick, concrete, or other masonry surface when moisture moves through and evaporates on the masonry. May also be caused by free alkalies leached from mortar, grout, or adjacent concrete.

EIP: Ethylene Interpolymer

Elasticity: the property of matter by virtue of which it tends to return to its original size and shape after removal of a stress or force which caused a deformation.

Elastomer: natural or synthetic material which, at room temperature, can be stretched under low stress and, upon immediate release of the stress or force, will return quickly to its approximate original dimensions.

Elastomeric: the elastic, rubber-like properties of a material that will stretch when pulled and will return relatively quickly to its original shape when released.

Elastomeric Coating: a coating system which, when fully cured, is capable of being stretched at least twice its original length (100% elongation) and recovering to its original dimensions.

Electrolyte: a liquid, most often a solution, that will conduct current.

Elongation: the ability of a material (e.g., roofing membrane) to be stretched by the application of a force.

Embedment: (1) the process of installing or pressing-in a reinforcement felt, fabric, mat or panel uniformly into bitumen or adhesive; (2) the process of pressing granules into coating during the manufacture of factory-prepared roofing; (3) the process whereby ply sheet, aggregate, or other roofing components settle into hot- or cold-applied bitumen via the force of gravity.

Embrittlement: the loss of flexibility or elasticity of a material. The transition of a flexible material to a brittle state.

Emulsion: a dispersion of fine particles or globules in a liquid. (See Asphalt Emulsion and Bitumen Emulsion.)

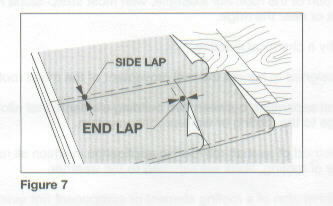

End Lap: the distance of overlap where one ply, panel, or piece extends beyond the end of the immediately adjacent underlying ply, panel, or piece. (See Figure 7. )

Envelope (Bitumen-Stop): a continuous edge seal formed at the perimeter and at penetrations by extending the base sheet or one ply of felt beyond the edge of the membrane field plies. After all overlying field plies or insulation are in place, the extended ply is turned back onto the membrane and adhered. The envelope is intended to prevent bitumen seepage from the edge of the membrane.

EPDM: Ethylene Propylene Diene Monomer (See also Ethylene Propylene Diene Terpolymer.)

Epichlorohydrin (ECH): a synthetic rubber including two epichlorohydrin based elastomers. It is similar to and compatible with EPDM. ECH is typically used in lieu of EPDM when enhanced resistance to animal fat or other oils is needed.

Epoxy: a class of synthetic, thermosetting resins that produce tough, hard, chemical-resistant coatings and adhesives.

Equilibrium Moisture Content (EMC): (1) the moisture content of a material stabilized at a given temperature and relative humidity, expressed as percent moisture by weight; (2) the typical moisture content of a material in any given geographical area.

Equiviscous Temperature (EVT): the temperature at which a bitumen attains the proper viscosity for built-up membrane application.

Equiviscous Temperature (EVT) Application Range: the recommended bitumen application temperature range. The range is approximately 25°F (1 4°C) above or below the EVT, thus giving a range of approximately 50°F (28°C). The EVT Range Temperature is measured in the mop cart or mechanical spreader just prior to application of the bitumen to the substrate.

Equiviscous Temperature (EVT) for Asphalt: the recommended EVT for roofing asphalt (ASTM D312, Type I, 11, 111, or IV) is as follows:

- Mop Application: the temperature at which the asphalt's apparent viscosity is 125 centipoise (0.125 Pass).

- Mechanical Spreader Application: the temperature at which the asphalt's apparent viscosity is 75 centipoise (0.075 Pans).

Note: If there are simultaneous mop and mechanical spreader applications, in order to avoid the use of two kettles, the EVE for mechanical spreader application may be used for both application techniques.

Equiviscous Temperature (EVA) for Coal Tar: the recommended EVT for roofing coal tar (ASTM D 450, Type I or lil) is the temperature at which the coal tar's apparent viscosity is 25 centipoise (0.025 Pans).

Ethylene Interpolymers (EIP): a group of thermoplastic compounds generally based on PVC polymers from which certain single-ply roofing membranes can be formulated.

Ethylene Propylene Diene Terpolymer (EPDM): designated nomenclature of ASTM for a terpolymer of ethylene, propylene, and a diene. EPDM material is a thermosetting synthetic elastomer.

EVT: Equiviscous Temperature

Exhaust Ventilation: air that is typically vented or exhausted from the roof cavity, typically through vents installed on the upslope portion of the roof. For example, with most steep-slope roof assemblies exhaust vents are typically located at or near the ridge.

Exotherm: heat generated by a chemical reaction.

Expansion Cleat: a cleat designed to handle thermal movement of the metal roof panels.

Expansion Joint: a structural separation between two building elements that allows free movement between the elements without damage to the roofing or waterproofing system.

Exposed-Nail Method: a method of asphalt roll roofing application in which all nails are driven into the adhered, overlapping course of roofing. Nails are exposed to the weather.

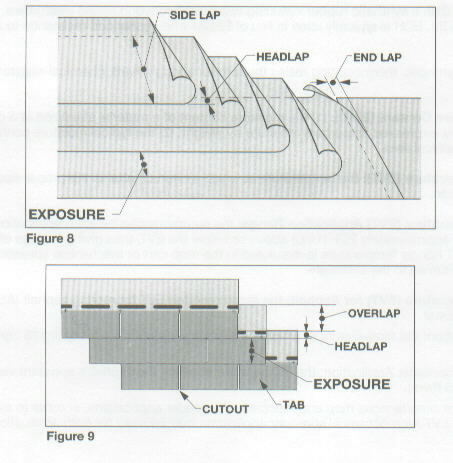

Exposure: (1) the traverse dimension of a roofing element or component not overlapped by an adjacent element or component in a roof covering. For example, the exposure of any ply in a built-up roof membrane may be computed by dividing the felt width minus 2 inches (51 mm) by the number of shingled plies; thus, the exposure of 36 inch (91 4mm) wide felt in a shingled, four-ply membrane should be approximately 84/~ inches (21 6mm) (See Figure 8); (2) the dimension of sidewall or roofing covering that is not covered or overlapped by the upslope course of component. The typical exposure for a standard-size, 3-tab shingle is 5 inches (127mm), depending upon manufacturer specifications. (See Figure 9.)

Extrusion: a manufacturing process which consists of forcing batched and formulated material (which may be molten) through an orifice called a "die." The shape and dimensions of the orifice determine the shape and dimensions of the finished product. Extrusion is one method by which some single-ply roofing membranes are manufactured.

Eyebrow: a dormer, usually of small size, whose roof line over the upright face is typically an arched curve, turning into a reverse curve to meet the horizontal at either end. Also, a small shed roof projecting from the gable end of the larger, main roof area.